2026! BambooPrefab! www.saevfors.se

Time for change! This web site will, before closing, now focus on

Bamboo Technical detailing for:

Conflict with industrial/planar materials.

Dimensional standards.

Template rigs for large scale production.

Computerized tools (CNC, 3Dprint etc)

Previously made research and development on this site can still be sourced under the Archive tabs.

The natural features of bamboo given by nature make each individual culm unique:

often curved, more or less tapered, sometimes with oval or irregular section, varying inter-node lengths… The strength properties of tension and compression can vary considerably according to the different 1000+ bamboo species.

Matching bamboo with planar and rectilinear materials is therefore a huge challenge. Industrialization and modular design necessary for prefabrication become virtually impossible without intermediate steps to circumvent these conflicts.

Ingemar Saevfors

Architect/Urban planner with longtime lnks to Africa, the Americas and SE Asia, specializes in innovative building technologies for low income regions.

ingemar@saevfors.se

Kallangsvag 73, 18144 Lidingo, Sweden +46 703936761 www.saevfors.se

PREFAB IN FOCUS NOW: The daunting perspective of housing another two-three billion people until 2050 on the planet is now further exacerbated by the fast climate change!

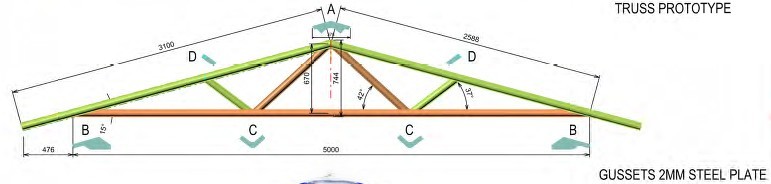

WEBSITE UNDER UNDER REORGANIZATION RIGHT NOW, BUT HERE ARE A FEW EXAMPLES OF PREFAB ADAPTATIONS COMING UP: Roof trusses and purlins are normally quite expensive items requiring high-end timber or metal profiles to meet the structural reliability. These components can easily be replaced by low-cost bamboo elements with their high tensile capacity, trimmed to a dimensional standard and combined with an efficient back-to-back gusset joint design.

Roof trusses and purlins are normally quite expensive items requiring high-end timber or metal profiles to meet the structural reliability. These components can easily be replaced by low-cost bamboo elements with their high tensile capacity, trimmed to a dimensional standard and combined with an efficient back-to-back gusset joint design.Urban multi-story bamboo housing

The great CO2 sink capacity makes fast-growing bamboo an obvious large scale option for construction materials. Multi-story - at a reasonable density, because of the never-ending suburban sprawl with more transport nightmares paralyzing the economy.

L-shaped column with buckling prevention for 3-storeys in cooperation with KTH, Technical University, Stockholm

Honeycomb wall module with loadbearing culm / Standard frame confronts bamboo culm curvature